-

Power Supply Nitrogen gas, compressed air or purified natural gas

Power Supply Nitrogen gas, compressed air or purified natural gas -

Control Objects Surface safety valve (Master safety valve or wing safety valve)

Control Objects Surface safety valve (Master safety valve or wing safety valve) -

Applicable Service Conditions Normal temperature conditions with clean and continuous gas supply

Applicable Service Conditions Normal temperature conditions with clean and continuous gas supply -

Features

Features 1. Simple control logic; easy maintenance; stable & reliable system.

2. Stable and continuous gas supply is required.

3. Control surface safety valve (including master safety valve and wing safety valve).

4. Suitable for complex geological conditions with extensive control.

5. Components and units are manufactured from corrosion-resistant SS.

6. Optional: temperature/pressure data acquisition, remote-control solenoid valves, RTU unit and SCADA functions.

-

Power Supply Manual hydraulic pump, electro-hydraulic pump, and pneumatic-hydraulic pump

Power Supply Manual hydraulic pump, electro-hydraulic pump, and pneumatic-hydraulic pump -

Control Subjects Sub-surface safety valve, master safety valve, wing safety valve.

Control Subjects Sub-surface safety valve, master safety valve, wing safety valve. -

Applicable Service Conditions Suitable for all types of environments

Applicable Service Conditions Suitable for all types of environments -

Features

Features 1. Wide applicable ambient temperature range, with a minimum of -46 degrees Celsius.

2. The hydraulic pump can be manually, electrically, or pneumatically operated in a flexibly.

3. Can be used to control a single or multiple safety valves (sub-surface safety valve/surface safety valve).

4. Components and parts are manufactured from corrosion-resistant SS material.

5. An accumulator is used for driving power storage and compensating control pressure changes caused by night-time/daytime temperature fluctuations.

6. Optional functions such as temperature/pressure data acquisition, remote control by solenoid valves, RTU and SCADA control.

-

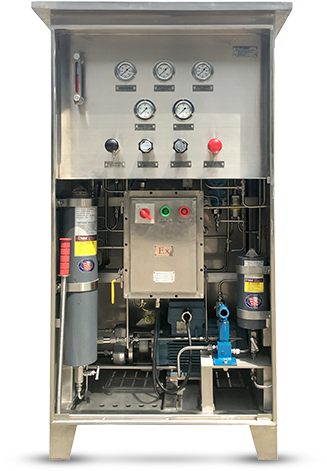

Power Supply Nitrogen gas, compressed air or purified natural gas

Power Supply Nitrogen gas, compressed air or purified natural gas -

Control Objects Sub-surface safety valve, master safety valve, wing safety valve

Control Objects Sub-surface safety valve, master safety valve, wing safety valve -

Applicable Service Conditions According to customer's need

Applicable Service Conditions According to customer's need -

Features

Features 1. The sub-surface safety valve is controlled by hydraulic pressure, and the surface safety valve by pneumatic pressure.

2. Suitable for complex geological conditions with extensive control distances.

3. Components and units are manufactured from corrosion-resistant SS.

4. Optional: temperature/pressure data acquisition, remote-control solenoid valves, RTU unit and SCADA functions.

-

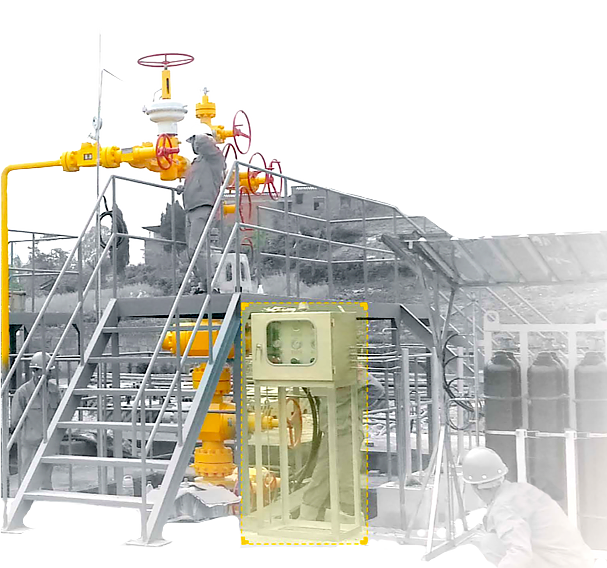

Power Source Local gas supply, pneumatic-hydraulic pump, and electro-hydraulic pump

Power Source Local gas supply, pneumatic-hydraulic pump, and electro-hydraulic pump -

Control Objects Sub-surface safety valve, master safety valve, wing safety valve

Control Objects Sub-surface safety valve, master safety valve, wing safety valve -

Applicable Service Conditions Offshore platforms, onshore cluster wells

Applicable Service Conditions Offshore platforms, onshore cluster wells -

Functional Features

Functional Features 1. Customized design as per on-site conditions and specific requirements.

2. In-series and in-parallel mode for well logic judgments.

3. Components and units are manufactured from corrosion-resistant SS.

4. Optional: temperature/pressure data acquisition, remote-control solenoid valves, RTU unit and SCADA functions.

-

Power Supply Nitrogen gas, compressed air or purified natural gas

Power Supply Nitrogen gas, compressed air or purified natural gas -

Control Objects Surface safety valve (Master safety valve or wing safety valve)

Control Objects Surface safety valve (Master safety valve or wing safety valve) -

Applicable Service Conditions Normal temperature conditions with clean and continuous gas supply

Applicable Service Conditions Normal temperature conditions with clean and continuous gas supply -

Features

Features 1. Simple control logic; easy maintenance; stable & reliable system.

2. Stable and continuous gas supply is required.

3. Control surface safety valve (including master safety valve and wing safety valve).

4. Suitable for complex geological conditions with extensive control.

5. Components and units are manufactured from corrosion-resistant SS.

6. Optional: temperature/pressure data acquisition, remote-control solenoid valves, RTU unit and SCADA functions.